charpy impact test results for 1018 steel|charpy impact test cheat sheet : wholesaling Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact . Step sister Izzy is railing her brother's fuck-stick real fine

{plog:ftitle_list}

WEBISBN: 6559571289. Language: português. Gêneros: Ficção, Romance, Aventura, Humor. Views 9. Avalie o livro. Sinopse o livro (resumo) «Imperfeitos» Christina Lauren. Olive se sente como a gêmea azarada .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .

Analysis and Results. For each type of material, plot the fracture energy versus the temperature. (All data) For each type of material, plot the lateral expansion versus the temperature. (All .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and . In this paper, we present the results from CVN impact tests on dual phase 590 (DP590) steel and AISI-1018 steels. ASTM testing procedure E-23 was followed. Tests were .

Finally, the instrumented Charpy impact test can provide useful comparative quantitative data with relatively simple testing procedures and easily manufactured specimens. The DBTT is . This lab report will compare the different impact strengths and energy absorbed on impact by three specimens of ASTM E-23 standard 1018 Steel at three different temperatures .In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .Nov 11, 2016

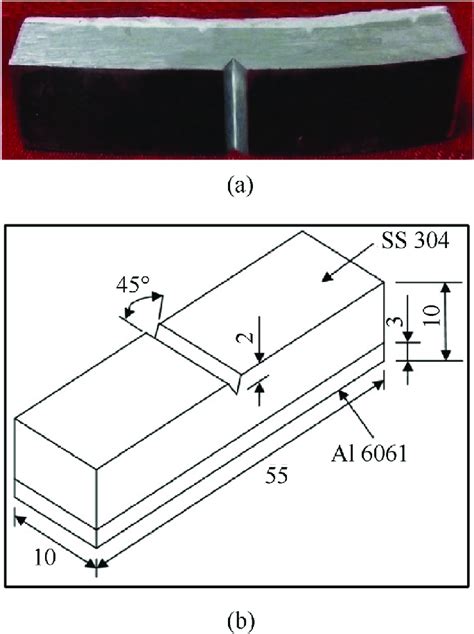

SATEC systems impact tester, 1018 Steel and 304 Stainless Steel were examined at – 196 ºC, - 78 ºC, 0 ºC, 24 ºC and 100 ºC. . characteristics is Charpy impact test. 1,2 Charpy impact test is designed to measure the impact toughness, the energy absorbed, during fracture at a high strain rate as a function of temperature. . the results .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant• Charpy V-notch impact testing machine (figure 1.3.1) • Specimens: 1018 CR steel & 6061-T6 aluminum • Thermometer • Water • Dry ice • Hot plate • Oven • Bowls, tongs • Heavily insulated gloves, • Safety glasses . Analysis and Results • For each type of material, plot the fracture energy versus the temperature. (All

• Charpy V-notch test pecimens of 6061-T6 aluminum and 1018 (hot rolled) or A36 steel • Charpy testing machine with 800-mm long pendulum arm and 22.6-kg impact head • Type K thermocouple and digital readout unit • Beakers of room-temperature water, warm water and boiling water • Beakers of plain iced water Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch.The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .

Results and Discussion 3.1 Results This section of the lab report will present the results of the Charpy impact test of 1018 annealed steel Charpy notched specimens in line with ASTM Standard E-23. The test is performed 4 times to .

The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point of stress concentration within the specimen and improves the reproducibility of the results.Constructing a building using steel beams that haven’t been tested for their ability to withstand sudden external forces could lead to catastrophic structural failure. By subjecting materials to Charpy Impact Testing, manufacturers and engineers gain invaluable insights into how various materials will respond to real-world operating .Instrumented Charpy impact test equipment can continuously record data on displacement, force, energy, time, etc., and save them in PC [15–18]. . AISI-1018, and DP590 Steels Steel Yield strength (MPa) Ultimated tensile strength (MPa) Elongation (%) 3Mn–Si–Ni 1250 1550 16 DP590 350 602 24–30 AISI-1018 275 475 38 . Results and .

standard charpy impact test

• Charpy V-notch test specimens of 6061-T6 aluminum and 1018 (hot rolled) or A36 steel • Charpy testing machine with 800-mm long pendulum arm and 22.6-kg impact head • Type K thermocouple and digital readout unit • Beakers of room-temperature water, warm water and boiling water • Beakers of plain iced water Charpy impact test and three-point bending test on 32 mm and 50 mm thick Q690 high-strength steel were carried out according to the environmental features of plateau low temperature to assess the .

Charpy V-Notch impact energy on dual phase 590 steel as well as AISI-1018 structural steel is presented. Tests were conducted at temperatures ranging from −120 °C (−184 °F) to 90 °C (194 °F). Specimens oriented in both L–T and T–L directions were tested for the DP590. Corrections for the reduced thickness was made and justified.

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .2 Charpy impact test result of 1018 carbon steel bars Testing media/condition Impact energy (ft-Ib) 3 Testing temperature (C) -196 4 10.0 3.5 10.0 2.5 -78 4.5 Liquid nitrogen (N2()) Dry ice (CO2(s)) Room temperature Boiling water 21.0 .Download Table | Summary of tensile test results for the 1018 steel. from publication: The Use of Genetic Algorithms to Calibrate Johnson-Cook Strength and Failure Parameters of AISI/SAE 1018 .

Charpy Impact Test. Full Code MET0102215. Module Type. E-learning. . - Interpret the effects of a notch, and typical Charpy test results; - Identify the triaxial tension, Charpy testing equipment, and Charpy test Fractures; . steelHub. Products. Courses Simulators Workshops SteelTalks. Solutions. Plans for teamsCharpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the Charpy Impact Test are important because they determine the right material for a specific application. The use of materials that do not meet the requirements can have fatal consequences. When coldness and strong forceCharpy V-notch specimens of 6061 T6 aluminum and 1018 (hot rolled) or A36 steel Charpy testing machine with 800-mm long pendulum arm and 22.6-kg impact head . One of the most dramatic results of Charpy impact tests is in the form of plots of impact energy versus temperature in which sigmoidally-shaped curves (See Fig. 3) show substantial .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount of energy absorbed by the specimen during fracture. . When reporting the results of a Charpy test, the .A Charpy impact test (CVN test) is used to measure the fragile-ductile temperature and as a quality control test. This evaluation's simplicity allows converting energy values to fracture toughness . Engineering performance of AHSS in many areas have shown that they are superior to the conventional steels such as mild steel, IF (interstitial-free) steel or even HSLA (high strength, low alloy) steel. In this paper, we present the results from Charpy V-Notch impact tests on Dual Phase 590 (DP590) steel, which belongs to the family of AHSS.This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).

examples of charpy impact tests

perkin elmer polarimeter calibration

Contact D. H. Hill Jr. Library. 2 Broughton Drive Campus Box 7111 Raleigh, NC 27695-7111 (919) 515-3364. James B. Hunt Jr. Library. 1070 Partners Way

While Charpy results cannot be directly applied to structural design requirements, a number of correlations have been made between Charpy results and fracture toughness. Topics Charpy testing , Cast metal alloys , Wrought steel , Steelmaking , Alloy composition , Ductile-to-brittle transition temperature , Notch impact toughness

perkin elmer polarimeter cell

charpy impact testing

web

charpy impact test results for 1018 steel|charpy impact test cheat sheet